Products

Professional Brass Ball Valve Manufacturer in China

We are one of the most professional brass ball valve manufacturers and exporters in China, providing full range brass ball valves from sizes 1/4” to 4” and pressure from PN10 to PN40, including brass water ball valves, brass gas ball valves, brass mini ball valves, compression brass ball valve, brass ball valves for PEX pipes and other related brass ball valves.

Guide to importing brass ball valves China

This is a comprehensive guide for importing brass ball valves from China, there are details of brass ball valves from many different aspects, including the definition of brass ball valves, functions of brass ball valves, features of of brass ball valves, advantages of of brass ball valves, the applications of of brass ball valves, the thread types of brass ball valves.

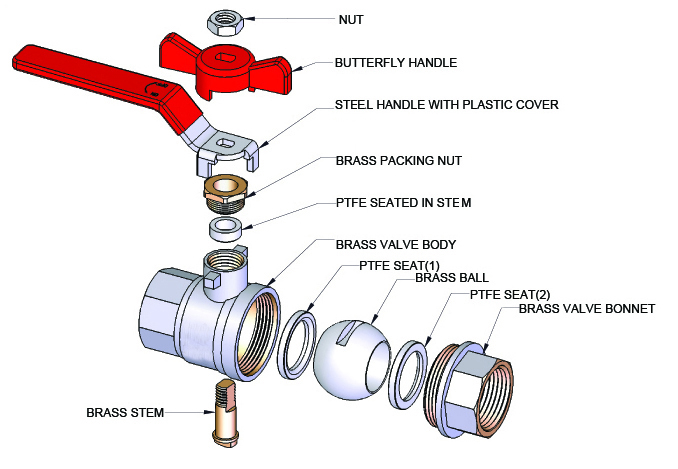

The design of brass ball valve

Brass ball valve is a type of brass valve that consisted with a brass ball inside of valve body. A brass ball valve mainly consists of brass valve body, valve bonnet, brass ball, valve handle and sealing parts.

Brass ball valve body and bonnet are hot forged brass material bars, which are main structure of brass ball valve, providing shield support for the brass ball valve, deciding the valve strength and working pressure. Brass ball valve body and bonnet can nickel-plated or rough brass color.

Brass valve ball is core part to determine the sealing and operation of brass ball valve, forged part with polishing and chrome-plating.

The brass valve handle is to open and close the brass ball valve, there are flat handle with PVC sleeve, butterfly handle, T-handle.

The sealing parts including PTFE seats for valve ball, O-ring or PTFE seat for valve stem. They are very important parts of brass ball valve in term of flow media tightness.

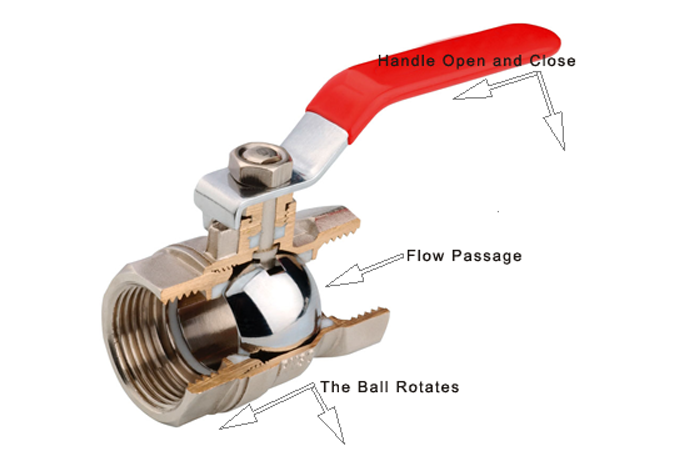

How brass ball valve works

The opening and closing part of the brass ball valve is controlled by the valve ball inside, which rotates around an axis perpendicular to the channel. When operate the brass ball valve handle, the valve ball rotates with the valve stem to achieve the purpose of opening and closing. The brass ball valve can be closed tightly with only a 90-degree rotation and a small torque.

The functions of brass ball valves

The brass ball valve is mainly used for cutting off, distributing and changing the flow direction of the medium in the pipeline. The V-shaped opening brass ball valve also has a good flow adjustment function.

The main features of the brass ball valve is its compact structure, low fluid resistance, and the brass ball valve basically has no flow resistance. Reliable seal, simple structure, small size, light weight, convenient maintenance, sealing surface and spherical surface are often closed, not easy to be eroded by the medium, easy to operate and maintain, suitable for general working media such as water, solvent, acid and natural gas, and It is also suitable for media with harsh working conditions, such as oxygen, hydrogen peroxide, methane and ethylene, etc. It is widely used in various industries. When fully open or fully closed, the sealing surface of the ball and valve seat is isolated from the medium. When the medium passes, it will not cause The erosion of the valve sealing surface has a wide range of applications, with a diameter ranging from a few millimetres to a few meters, and can be applied from high vacuum to high pressure. The brass ball valve body can be integral or combined.

Features of Brass Ball Valves

The brass ball valve has the action of rotating 90 degrees, with a circular through hole or channel passing through its axis. The brass ball valve is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. It only needs to rotate 90 degrees and a small torque can be closed tightly. Brass ball valves are most suitable for switching and shut-off valves, but recent developments have designed ball valves to throttle and control flow, such as V-shaped ball valves. The main characteristics of the brass ball valve specifications are its compact structure, reliable sealing, simple structure, and convenient maintenance. The sealing surface and the spherical surface are often in a closed state, which is not easy to be eroded by the medium and is easy to operate.

It is suitable for water, solvents, acids and natural gas. Such as general working media, but also suitable for media with harsh working conditions, such as oxygen, hydrogen peroxide, methane and ethylene, etc., which are widely used in various industries. The brass ball valve body can be integral or combined.

Advantages of Brass Ball Valves

1. The fluid resistance is small, and the brass ball valve basically has no flow resistance.

2. Simple structure, small size and light weight.

3. Close and reliable. It has two sealing surfaces, and the current sealing surface materials of brass ball valves are widely used in various plastics, which have good sealing performance and can achieve complete sealing. It has also been widely used in vacuum systems.

4. Easy to operate, fast opening and closing, only need to rotate 90° from fully open to fully closed, which is convenient for remote control.

5. Convenient maintenance, simple structure of the ball valve, generally movable sealing ring, easy to disassemble and replace.

6. When fully open or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium. When the medium passes, it will not cause erosion of the valve sealing surface.

7. It has a wide range of applications, with a diameter ranging from a few millimetres to a few meters, and can be applied from high vacuum to high pressure.

8. Because the brass ball valve has the wiping property during the opening and closing process, it can be used in the medium with suspended solid particles.

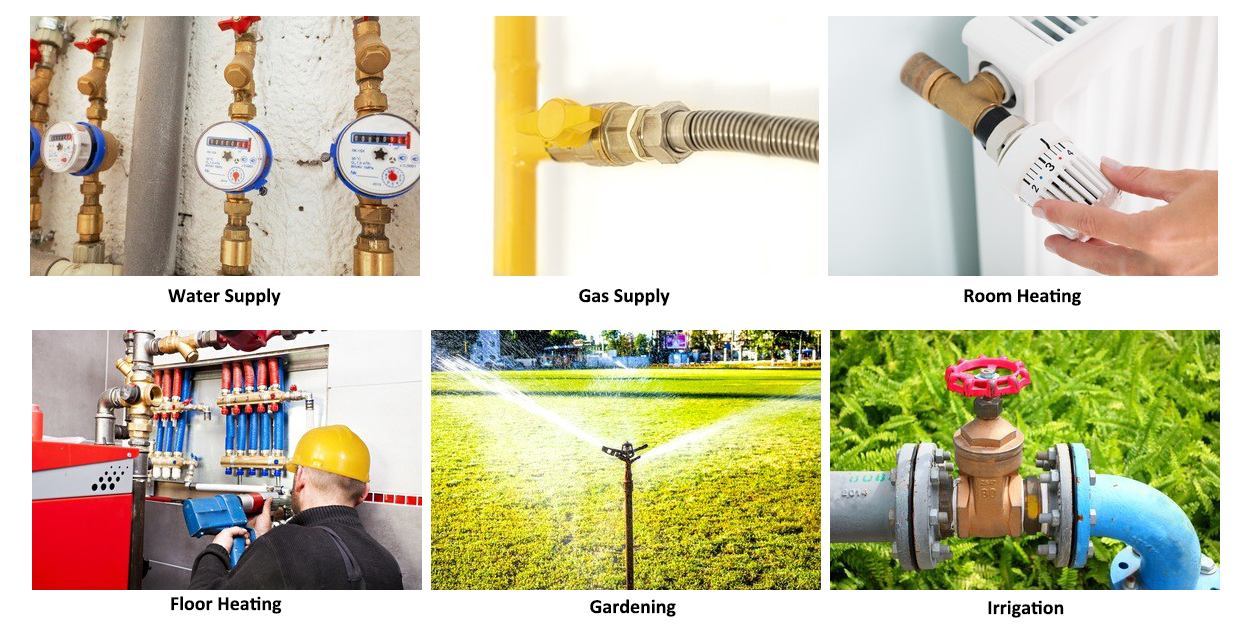

The applications of brass ball valves

Brass ball valves are widely used in chemical, petrochemical, petroleum, paper-making, mining, electric power, liquefied gas, food, pharmaceuticals, water supply and drainage, municipal administration, mechanical equipment, electronic industry, urban construction and other fields.

Brass ball valves are used mostly for pipelines carrying water or gas. The ends of these valves are compatible with PEX pipes. A brass ball valve consists of forged brass rings with a ball paired to form a conjugate. The valve is highly impermeable and does not allow even moisture. It can maintain temperature differences also. The primary purpose of the valve is to keep two sections of the pipe isolated from each other when it is in a shut state. Any leakage renders it useless and the valve loses its value. It has to be absolutely leak-proof as at times it is employed at very crucial points of a pipeline. The design consists of both thread type as well as sweat type to solder with the pipes.

How to choose brass ball valves

In terms of selecting the brass ball valve, it is essential to check its weight. The brass ball valves are exceptionally light and durable, which makes them unique in the hoard of other valves and playing significant roles in various sectors.

It is necessary to determine the amount of pressure that has to pass from the brass ball valve purchase, which will adjudicate the size of the brass ball valve needed. After all, it is necessary for the valve to handle the pressure of the liquid flow.

In order to choose the right brass ball valve, identifying the pressure level is also imperative because it will help in selecting the specialized valve with the material involved.

When it comes to selecting the brass ball valve, characterizing its usage is extremely important because specialized valves are available for the chemical industry or radioactive waste management and much more. The users cannot take the risk of using any brass ball valve for the flow of special liquids.

Types and Classifications of Brass Ball Valves

According to the pressure, brass ball valves can be divided into:

1). Low pressure brass ball valves: (nominal pressure) ≤1.6MPa

2). Medium pressure brass ball valves: (nominal pressure) 2.5~6.4MPa

3). High pressure brass ball valves: (nominal pressure) 10~80MPa

4). Ultra high pressure brass ball valves: (nominal pressure) ≥100MPa

We mainly produce medium and low pressure brass ball valve, the marking on the valve body is ten multiples of Mpa, for example: PN10 equals 1MPa

According to functions, brass ball valves can be divided into:

1). Straight brass ball valves

2). Angle brass ball valves

3). Three-way brass ball valves

4). Brass mini ball valves

According to the working temperature of the medium, brass ball valves can be divided into:

1). Ultra-low temperature

2). Low temperature -100℃~ -40℃

3). Normal temperature -40℃~120℃

4). Medium temperature 120℃~450℃

5). High temperature>450℃

we mainly produce normal temperature brass ball valves.

According to the flow medium, brass ball valves can be divided into:

1). water brass ball valve

2). oil brass ball valve

3). gas brass ball valve

We currently produce civil use water ball valves and civil used gas ball valves. Gas valves are generally requires EN331.

According to the stem structure, brass ball valves can be divided into:

1). O-ring structure brass ball valves

2). Packing-gland structure brass ball valves

O-ring structure brass ball valves: specifically refers to the seal on the stem is sealed with a black rubber seal; the advantage of this structure is that the assembly procedure at the stem is relatively simple; the cost is relatively low; the disadvantage is that it is not repairable and has a low operating temperature range , Prone to aging.

Packing-gland structure brass ball valves: It specifically refers to the valve stem seal using PTFE plastic king seal; the advantages and disadvantages of this structure are opposite to the O-ring structure, and it is safer and can be applied to relatively high pressure environments.

According to the end connections, brass ball valves can be divided into:

1) Threaded connection brass ball valves

2) Compression connection brass ball valves

3) Flange connection brass ball valves

4) Welding /soldering brass ball valves

5) Hose connection brass ball valves

According to the flow medium, brass ball valves can be divided into:

1). water brass ball valve

2). oil brass ball valve

3). gas brass ball valve

We currently produce civil use water ball valves and civil used gas ball valves. Gas valves are generally requires EN331.

According to the stem structure, brass ball valves can be divided into:

1). O-ring structure brass ball valves

2). Packing-gland structure brass ball valves

O-ring structure brass ball valves: specifically refers to the seal on the stem is sealed with a black rubber seal; the advantage of this structure is that the assembly procedure at the stem is relatively simple; the cost is relatively low; the disadvantage is that it is not repairable and has a low operating temperature range , Prone to aging.

Packing-gland structure brass ball valves: It specifically refers to the valve stem seal using PTFE plastic king seal; the advantages and disadvantages of this structure are opposite to the O-ring structure, and it is safer and can be applied to relatively high pressure environments.

According to the end connections, brass ball valves can be divided into:

1) Threaded connection brass ball valves

2) Compression connection brass ball valves

3) Flange connection brass ball valves

4) Welding /soldering brass ball valves

5) Hose connection brass ball valves

Contact Us Now

Enter your inquiry details, we will response within 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear